Difference between revisions of "Blog 17"

| Line 133: | Line 133: | ||

Cable connection: |

Cable connection: |

||

{| border=1 |

{| border=1 |

||

! pin !! function !! cable |

! pin !! function !! cable |

||

|- |

|- |

||

| 1 || Output B1 || Black (Connected with right wheel down) |

| 1 || Output B1 || Black (Connected with right wheel down) |

||

Revision as of 17:06, 16 November 2015

2 Wheel controlled car

I made this on the Raspbery Pi for the stepper motor and for 'electric wheels'.

Stepper motor version

Hardware I used on my Raspberry Pi:

- One RPi_UI board | (User Interface)

- Two 7FETs | (7FETs)

- Two Jumper cables M-F

- Two IDC cable 6 pin

- Two 28BYJ-48 Stepper Motor

Programming:

- Bash

The full car just went to be a carton box, with everything attached to it with tieraps.

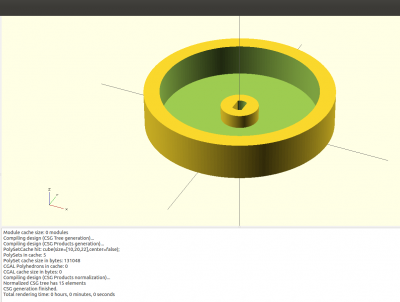

3D printed wheels code

I made the wheels in OpenSCAD and let them be printed out on a 3d printer. The diameter of the wheel is 60mm and is 12mm high. The hole in the middle was made to put in the 28BYJ-48 Stepper Motor. The OpenSCAD code:

$fs=0.2; $fa=2;

module stepperas(d=5, l=25, t=3)

{

difference()

{

cylinder (r=d/2 , h=l);

translate ([t/2, -5, -1]) cube([10, 20, l+2]);

translate ([-t/2-10, -5, -1]) cube([10, 20, l+2]);

}

}

difference()

{

union () {

difference () {

cylinder (r=60/2 ,h=12);

translate ([0, 0, 1.5])

cylinder (r=50/2, h=20);

}

cylinder (r=6,h=6);

}

translate ([0, 0, -1])

stepperas(5.2, 20, 3.2);

}

The result of the OpenSCAD code (Press F5 to see it in OpenSCAD):

Code

Here is a list of the commands one of each other, that you could send to the stepper motor.

#!/bin/bash #Address=spi0 address2=spi1 Address="bw_tool -s 50000 -a 88" Address2="bw_tool -S -D /dev/spidev0.1 -a 88" #800 is rotating a full circle Rot=800 Target=`$Address -R 41:i` Speed1=0x200 Speed2=0x100 #Speed3=0x50 #Speed4=0xff #Turn left $Address -W 43:$Speed1:b $Address -W 42:$Rot:i $Address2 -W 43:$Speed2:b $Address2 -W 42:$Rot:i sleep 10 #Turn Right $Address -W 43:$Speed2:b $Address -W 42:$Rot:i $Address2 -W 43:$Speed1:b $Address2 -W 42:$Rot:i sleep 10 #Go Forwards $Address -W 43:$Speed2:b $Address -W 42:-$Rot:i $Address2 -W 43:$Speed2:b $Address2 -W 42:$Rot:i sleep 10 #Go Backwards $Address -W 43:$Speed2:b $Address -W 42:$Rot:i $Address2 -W 43:$Speed2:b $Address2 -W 42:-$Rot:i sleep 10 #Spin right $Address -W 43:$Speed2:b $Address -W 42:$Rot:i $Address2 -W 43:$Speed1:b $Address2 -W 42:-$Rot:i sleep 10 #Spin left $Address -W 43:$Speed2:b $Address -W 42:-$Rot:i $Address2 -W 43:$Speed1:b $Address2 -W 42:$Rot:i

'Electric wheels' version

Hardware I used on my Raspberry Pi:

- One RPi_UI board | (User Interface)

- One Motor | (Motor)

- One Cable, 4 Pin (I2C), F-F

- Two single Jumper cables M-M

- Two electric wheels

- Soft cables ( To connect to the motor and the wheels )

- One dongle

To put the wheels on the board: I just made some holes and put some tieraps around the board to hold the electric wheels.

Cable connection:

| pin | function | cable |

|---|---|---|

| 1 | Output B1 | Black (Connected with right wheel down) |

| 2 | Output B2 | Red (Connected with right wheel up) |

| 3 | Output A1 | Black (Connected with left wheel down) |

| 4 | Output A2 | Red (Connected with left wheel top) |

| 5 | GND | White Jumper Cable M-M (Connected with the ground from the battery) |

| 6 | Vin | Red Jumper Cable M-M (Connected with the power from the battery) |

The cables and jumper cables can of course be different colors, but I told the color for the images. The reason I used the jumper cable M-M is because it is easier to put in the battery.

Programming:

- Bash

Script:

#!/bin/bash #Wheel A left forward #Wheel B Right forward # X is forwards - Y is backwards #Wheels at front #20 A backwards #21 A forwards #22 A stop #30 B backwards #31 B forwards #32 B stop Address="bw_tool -I -D /dev/i2c-1 -a 90" Speed="80" Speed2="40" while true; do BUTTON=`bw_tool -I -D /dev/i2c-1 -a 94 -R 30:b` if [ $BUTTON = "20" ]; then #Car going forwards $Address -W 21:$Speed:b $Address -W 31:$Speed:b fi if [ $BUTTON = "10" ]; then #Car going backwards $Address -W 20:$Speed:b $Address -W 30:$Speed:b if [ $BUTTON = "08" ]; then #Car going left $Address -W 21:$Speed2:b $Address -W 31:$Speed:b fi if [ $BUTTON = "04" ]; then #Car going right $Address -W 21:$Speed:b $Address -W 31:$Speed2:b fi if [ $BUTTON = "02" ]; then #Car Stop $Address -W 22:$Speed:b $Address -W 32:$Speed:b fi if [ $BUTTON = "01" ]; then exit fi sleep 1 done

Other movements:

#Spinning right bw_tool -I -D /dev/i2c-1 -a 90 -W 20:80:b bw_tool -I -D /dev/i2c-1 -a 90 -W 31:80:b #Spinning left bw_tool -I -D /dev/i2c-1 -a 90 -W 21:80:b bw_tool -I -D /dev/i2c-1 -a 90 -W 30:80:b

I think the code pretty much explains itself with the extra info I have given it. I used the push buttons as example of how it could be used. All the protocols can been found in Motor protocol.

Useful links

- Working with a 7FETs Stepper motors Blog 15

- Working with multiple 7FETs Stepper motors Blog 16

- Blog list ( Overview of all my posts )

- Motor protocol

- OpenSCAD documentation